Torque Motor Explained: How They Work and Why They’re Essential for Precision Applications

A torque motor is a type of electric motor designed to provide high torque at low speeds, which makes them ideal for precision applications that require controlled movements. These motors operate in a way that allows them to directly drive a load without the need for gears or belts. The key advantage of a torque motor lies in its ability to deliver consistent and reliable torque even when the motor is at a standstill or operating at very low RPMs, which is essential for tasks that demand high accuracy. Whether in robotics, CNC machines, or automotive systems, torque motors help to achieve the stability and precision that other types of motors simply cannot provide.

The primary appeal of a torque motor is its direct-drive design. Unlike traditional motors, which use gear systems or belts to transfer power to the load, a torque motor connects directly to the load, which reduces mechanical complexity. This not only improves reliability by eliminating the need for additional components that can wear out but also boosts efficiency. Torque motors are designed to offer greater precision in tasks such as lifting, rotating, or positioning, which makes them an essential tool in a variety of industries that require meticulous control over movement.

Understanding Torque Motors: Types and Functions

Torque motors are available in various types, each offering unique advantages depending on the application. DC torque motors, for example, are known for their ability to operate efficiently at low speeds. They are used primarily in robotics and automation where high precision is necessary. DC torque motors allow for smooth and accurate control over speed and position, making them ideal for complex movements such as those required in robotic arms or conveyor systems.

Another popular variant is the brushless torque motor, which has grown in popularity due to its superior efficiency and longevity. Unlike traditional motors, brushless torque motors do not use brushes to transfer current, which results in less wear and tear, reduced maintenance, and better overall performance. The absence of brushes also reduces electrical noise, which can be a concern in sensitive applications. Brushless torque motors are widely used in industries where long-lasting, reliable performance is crucial, such as medical devices, aerospace, and high-end manufacturing.

Applications of Torque Motors in Precision Machinery

Torque motors are indispensable in industries where precision and control are paramount. One of the most common uses of torque motors is in robotics, where they enable accurate and smooth movements. These motors can handle the complex tasks of gripping, rotating, and positioning with great precision. Robotics applications, whether in assembly lines, surgical procedures, or research laboratories, rely heavily on torque motors to achieve the necessary accuracy and repeatability.

Another critical application of torque motors is in CNC (computer numerical control) machines. CNC machines are used for cutting, drilling, and shaping materials with exact specifications, making them vital in industries such as manufacturing and automotive production. The precision required for these tasks demands a reliable motor that can maintain consistent torque, and this is where the torque motor excels. By delivering high torque at low speeds, torque motors ensure that CNC machines can perform these operations without compromising on quality or efficiency.

Benefits of Torque Motors Over Conventional Motors

When compared to traditional motors, torque motors offer several distinct advantages. One of the most significant benefits is their ability to maintain torque at low speeds. Most conventional motors experience a drop in torque as the speed decreases, making them less suitable for precision applications. Torque motors, on the other hand, are designed specifically to provide consistent torque even at very low speeds or when the motor is stalled. This makes them ideal for applications where the motor must hold a position or apply force without moving, such as in lifting equipment or winding machines.

Another major advantage of torque motors is their reduced maintenance requirements. Since they have fewer moving parts compared to traditional motors that rely on gear systems or belts, torque motors are less prone to mechanical failure. This can significantly reduce downtime and maintenance costs in industries that rely on high-precision machinery. Additionally, the direct-drive design of a torque motor eliminates the friction and wear that is typically associated with gears and belts, which contributes to a longer lifespan and more reliable performance.

The Role of Torque Motors in the Automotive Industry

Torque motors also play a crucial role in the automotive industry. They are used in a variety of systems, from electric vehicle steering to lifting mechanisms. For example, the “Yakuza 0 high torque motor 2.0” is a prime example of how torque motors can enhance the performance of automotive systems. In this case, the motor provides the necessary power to ensure smooth and precise operation of key vehicle components. Similarly, the “Torque Motor 2.4 Honda CRV” is used in various functions within the vehicle to optimize performance and provide reliability.

Moreover, the integration of torque motors in electric vehicles (EVs) has revolutionized the industry. Torque motors provide enhanced control over power distribution, which is essential for handling and braking in EVs. They allow for smoother acceleration and more precise movement in both high-speed and low-speed conditions, making them indispensable in modern automotive engineering.

Hydraulic Torque Motors and Their Industrial Applications

While most torque motors are electric, hydraulic torque motors also play a significant role in certain industrial applications. Hydraulic torque motors use fluid pressure to generate force, and they are typically used in heavy-duty machines where electric motors may not provide the necessary power. Industries such as construction, mining, and material handling rely on hydraulic torque motors for their durability and ability to perform under high loads. These motors are often used in applications such as drilling rigs, conveyors, and winches, where high torque and continuous operation are required.

The main benefit of hydraulic torque motors over electric models is their ability to produce large amounts of torque without the need for a large and bulky motor. In heavy industries, where machinery often operates in harsh environments, hydraulic torque motors provide the power and reliability needed to get the job done efficiently. They can operate at slower speeds and under heavy loads, making them ideal for industrial applications where the demand for torque is high and constant.

The Future of Torque Motors: Innovations and Market Growth

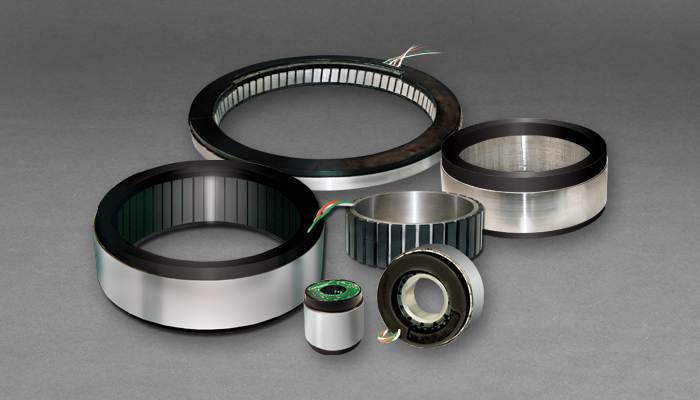

The torque motor market is expected to continue growing as industries increasingly recognize the need for high-precision motors. Advances in motor design are also making torque motors smaller, more efficient, and more powerful. For example, frameless torque motors are becoming increasingly popular due to their compact size and customizable features. These motors are ideal for applications where space is limited or where customization is required to fit into complex systems.

As industries like automation, robotics, and electric vehicles continue to expand, the demand for torque motors is likely to rise. The global market for torque motors is projected to see steady growth, driven by the increasing demand for precision in manufacturing, robotics, and automotive applications. With the potential for continuous innovation and improvements in efficiency, torque motors are expected to play a pivotal role in the development of new technologies and systems across various sectors.

Conclusion

Torque motors are a vital component in the world of precision machinery. Their ability to deliver consistent torque at low speeds, combined with their direct-drive design, makes them indispensable in applications requiring accuracy and reliability. Whether in robotics, CNC machines, or automotive systems, torque motors provide the power needed to perform intricate tasks with high precision. With continued advancements in technology, the future of torque motors looks promising, ensuring that industries can meet the ever-growing demands of high-precision applications.

FAQs

- What is a torque motor, and how does it work?

- How does a high torque motor differ from traditional motors?

- What are the advantages of using a brushless torque motor?

- In which industries are torque motors most commonly used?

- What is the role of hydraulic torque motors in heavy machinery?

- How do torque motors benefit automotive systems, especially in electric vehicles?

- Why is the torque motor market growing rapidly?

- How does a frameless torque motor work and why is it popular?

- What makes torque motors ideal for precision applications?

- How do torque motors compare to conventional DC motors in terms of performance?

You may also read: What Makes a Pergola with Polycarbonate Roof UK Special?